Automotive electrical systems are notoriously harsh environments for electronic components. Unlike the stable power from your wall outlet, your car’s voltage supply is subject to wild swings, from sudden spikes to significant drops. One critical scenario to consider is the voltage dip that occurs when starting your engine. It’s not uncommon for a 12V car battery to momentarily drop to around 9v Car Battery voltage, and even lower in cold weather. This fluctuation can wreak havoc on sensitive electronic devices if they aren’t properly protected.

Voltage spikes, or transients, are a major concern. These can be caused by various events, such as load dumps where a large electrical load is suddenly disconnected. These spikes can reach incredibly high voltages, potentially damaging any unprotected electronics connected to your car’s power system.

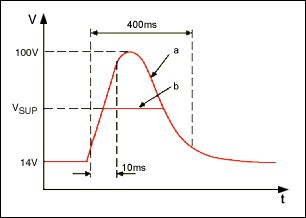

Automotive load dump transient voltage spike illustration, highlighting the need for robust voltage protection in car electronics.

As illustrated in the diagram above, sourced from a Maxim Integrated application note, automotive voltage transients can far exceed the nominal 12V, reaching levels that can destroy unprotected components. Therefore, robust protection is paramount.

However, it’s not just overvoltage that’s the problem. Undervoltage conditions, especially the dip down to 9V car battery levels during engine cranking, also present a significant challenge. When the voltage drops, a buck converter designed to step down voltage might struggle. The input current demand increases to maintain the output power, potentially leading to instability or failure in some boost converters if they are not designed to handle such wide input voltage variations.

Graph depicting automotive voltage drop to 9V during engine start, emphasizing the challenge for electronic voltage regulators to maintain stable output.

Maxim Integrated, in their application note, suggests various protection methods using components like varistors and Transient Voltage Suppressor (TVS) diodes to mitigate these issues. They even offer specialized chips designed specifically for automotive transient protection.

Automotive circuit diagram showcasing transient voltage suppressor (TVS) protection, critical for safeguarding electronics from voltage spikes and drops.

Ignoring these voltage fluctuations can lead to serious reliability problems, or worse, complete failure of your car’s aftermarket electronics. At a minimum, always fuse the power wire supplying any buck converter or sensitive device in your vehicle.

While chips like the LM2596 buck converter are rated for up to 40V input, which seems sufficient for normal car voltage, they can be pushed to their limits, especially when trying to deliver a stable 9V output at 3 amps during voltage dips. Furthermore, the LM2596 might not be the most efficient solution for higher current applications.

For more demanding applications, consider regulators like the LTC7813. The example circuit below demonstrates a 5V, 8A output, but it can be easily adjusted for a 9V car battery system output.

Circuit schematic of LTC7813 high-power buck-boost converter, suitable for maintaining 9V output even during cold cranking voltage drops.

The LTC7813 is a more advanced option, featuring a boost section which ensures operation even during cold cranking scenarios where the 9V car battery voltage drop is most pronounced. However, for simpler applications, it might be overkill.

Searching for “automotive buck voltage regulators” will reveal other suitable options. This next example offers a simpler approach:

Example circuit of automotive buck voltage regulator designed for a wide input range, adaptable for 9V output from fluctuating car battery voltage.

This circuit, while shown starting at a 15V input, can operate with lower input voltages, down to around 11V for a 9V output, by adjusting resistors RFB1 and RFB2. This makes it more suitable for handling the 9V car battery drop scenario.

Another chip to consider is highlighted in the following diagram:

Adjustable automotive voltage regulator circuit, emphasizing resistor configuration for setting a precise 9V output for car electronics.

You would need to carefully select the resistor values to achieve a precise 9V output. A significant advantage of this chip is its high efficiency:

Efficiency graph illustrating high performance of automotive voltage regulator, minimizing heat generation and maximizing power conversion from a 9V car battery system.

With around 95% efficiency, internal power loss is minimized to approximately 1 watt when delivering 3 amps. In contrast, the LM2596’s efficiency around 85% in similar conditions means significantly more heat dissipation, making efficiency a crucial factor when designing robust and reliable automotive electronics powered by a 9V car battery system during engine start and other voltage fluctuations.