From the early days of simple car ventilation to today’s sophisticated climate control, automotive air conditioning (A/C) systems have become incredibly advanced. Modern car A/C systems are intricate, comprising components like the compressor, condenser, evaporator, and refrigerant. Maintaining these complex systems is crucial, and monitoring the refrigerant pressure is a key aspect of this maintenance.

This article delves into the world of car A/C refrigerants, focusing on the commonly used R134a. We will provide a detailed A/c Pressure Chart for R134a and offer practical troubleshooting advice based on system pressure readings.

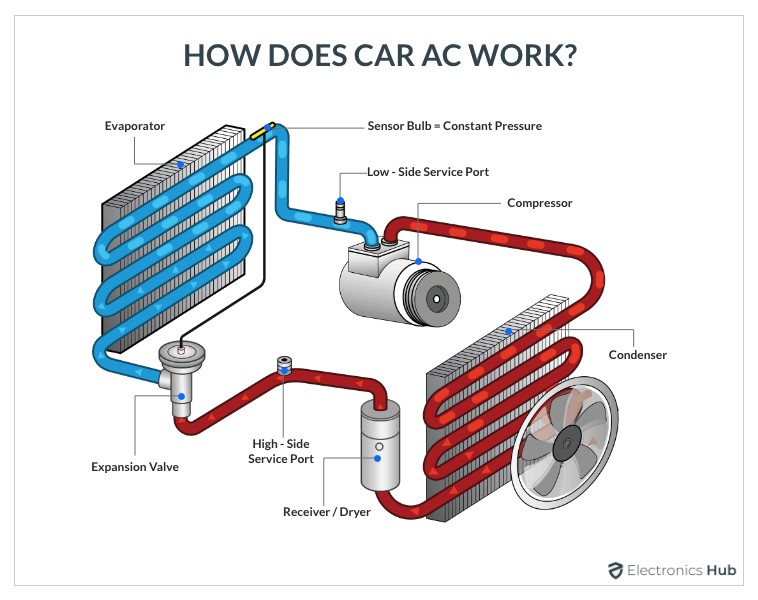

Understanding How Your Car A/C System Works

First, let’s break down the fundamental process of how your car’s A/C system cools the cabin. Refrigeration is essentially the process of removing heat from a specific area. In your car’s A/C, unwanted heat is transferred from inside the cabin to the outside environment. Think of your home refrigerator or a window air conditioner – car A/C works on the same principle.

This heat transfer is achieved using a special substance called refrigerant. This refrigerant circulates continuously, transitioning between a high-pressure liquid and a low-pressure gas. During this cycle, it absorbs heat and moisture from the cabin air, delivering cool, dry air in return.

Alt: Car AC system diagram showing compressor, condenser, expansion valve, evaporator, and refrigerant flow.

The compressor, condenser, accumulator (or receiver drier), and evaporator work together in a coordinated manner to produce cool air. The refrigerant is the core component in this cooling process. At low pressure and temperature, the refrigerant absorbs heat, changing from a liquid to a gas. To release the absorbed heat, the refrigerant is then condensed back into a liquid at high pressure and temperature.

For effective operation, a refrigerant needs specific properties:

- Non-flammable and non-explosive for safety.

- Low boiling point to facilitate heat absorption at low temperatures.

- Non-corrosive to prevent damage to system components and compatible with lubricants.

- Safe and non-toxic to minimize environmental and health risks.

- High latent heat value for efficient heat transfer.

- Easy to vaporize and condense within moderate temperature and pressure ranges.

Numerous refrigerants have been developed and used over time, each with varying properties. Some common and industry-approved refrigerants include:

- R-12 (Phased out due to environmental concerns)

- R-134a (Industry standard for many years)

- Freon (A brand name encompassing various refrigerants like Freon-11, R-12, R-22, etc.)

- Freeze-12 (R-12 replacement)

- GHG-HP

- Hot Shot

- Ikon-12

- R-406A

R134a: The Common Automotive Refrigerant

R-12, often known as Freon-12, was historically the primary refrigerant in cars and home refrigerators. However, due to its detrimental impact on the ozone layer, its use has been progressively banned since 1994.

R134a then emerged as the dominant standard in automotive A/C systems and other refrigeration applications. Its thermodynamic properties are quite similar to R-12, but it has a significantly reduced ozone depletion potential.

R134a boils at -26.8°C (-16.24°F) at atmospheric pressure. At a pressure of 10 psi, its boiling point increases to -10.6°C (12.92°F). If R134a is released in a room at normal atmospheric pressure and room temperature, it will instantly vaporize into a gas.

Temperature and pressure are directly linked for refrigerants. For R134a, a pressure of 35 psi (241 kPa) corresponds to a temperature of approximately 4.4°C (40°F). This relationship highlights the critical role of pressure and temperature in the condensation and evaporation cycles of R134a.

Important Note: While R134a became the standard, environmental concerns are again driving change. Since 2012, HFO-1234yf is becoming the preferred refrigerant in new vehicles due to its lower global warming potential. However, because R134a is still prevalent in many cars on the road, this article and the a/c pressure chart will concentrate on R134a systems.

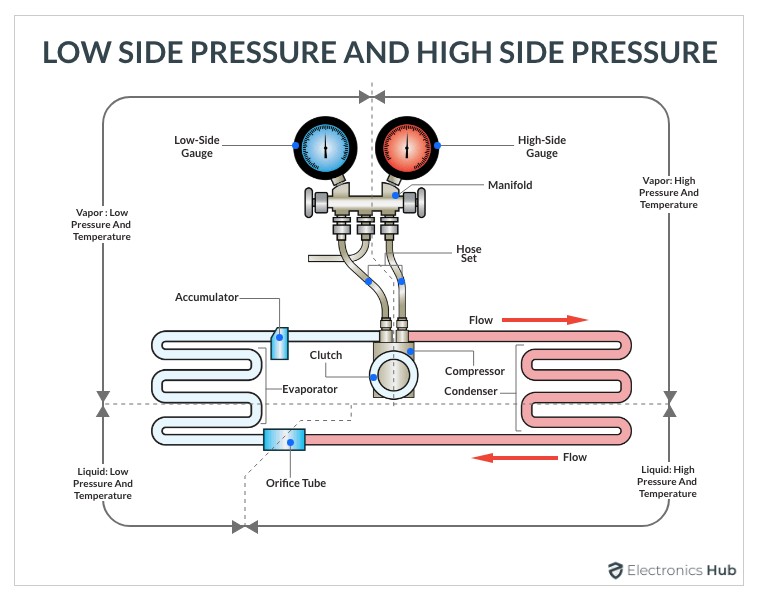

Understanding R-134A Low Side and High Side Pressure

Before we examine the a/c pressure chart for R134a, it’s important to understand why pressure measurement is so vital in car A/C diagnostics.

In a car A/C system, the refrigerant is continuously cycling between liquid and gas states within a sealed loop. The refrigerant’s pressure is directly related to its temperature.

Based on pressure readings at different points in the system, we categorize it into high-side and low-side pressure zones.

Alt: Car AC system diagram illustrating low-side pressure at the evaporator and high-side pressure at the condenser and compressor.

The compressor draws in low-pressure, gaseous refrigerant from the evaporator. It then compresses this gas, significantly increasing both its pressure and temperature. The point immediately after the compressor is the starting point of the high-pressure side.

This high-pressure, hot gas is then routed to the condenser. Airflow from the radiator fan cools the condenser, causing the high-pressure refrigerant gas to condense into a high-pressure liquid. This is where the refrigerant releases the heat it absorbed in the evaporator.

The high-pressure liquid then flows through the receiver/drier, which removes any moisture present in the refrigerant. From there, the filtered, high-pressure liquid passes through the thermal expansion valve or orifice tube. This valve restricts the flow, causing the high-pressure liquid to expand and transform into a low-pressure liquid.

This low-pressure liquid then enters the evaporator. Here, it absorbs heat from the cabin air, boiling and turning back into a low-pressure gas. This cooled air is then blown into the car’s cabin. The low-pressure gas then returns to the compressor, and the cycle begins again. The point after the evaporator, just before the compressor, is the low-pressure side measurement point.

Note: Service port locations can vary slightly. Some systems might have the low-side service port just before the compressor and the high-side service port just after the receiver/drier. Always consult your vehicle’s service manual for specific locations.

The R-134A A/C Pressure Chart

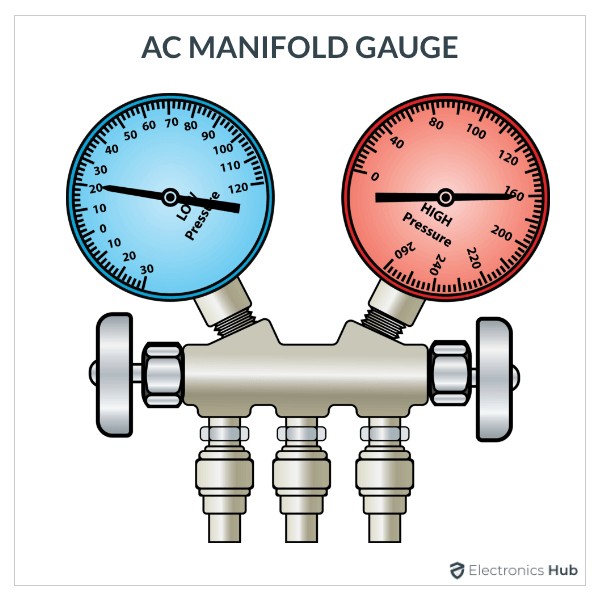

To measure the low-side and high-side pressures, technicians use a specialized tool called an A/C manifold gauge set. This device includes two pressure gauges – one for the low side (typically blue) and one for the high side (typically red) – connected to a manifold with hoses.

Alt: AC manifold gauge set with red and blue gauges and hoses for measuring car AC pressure.

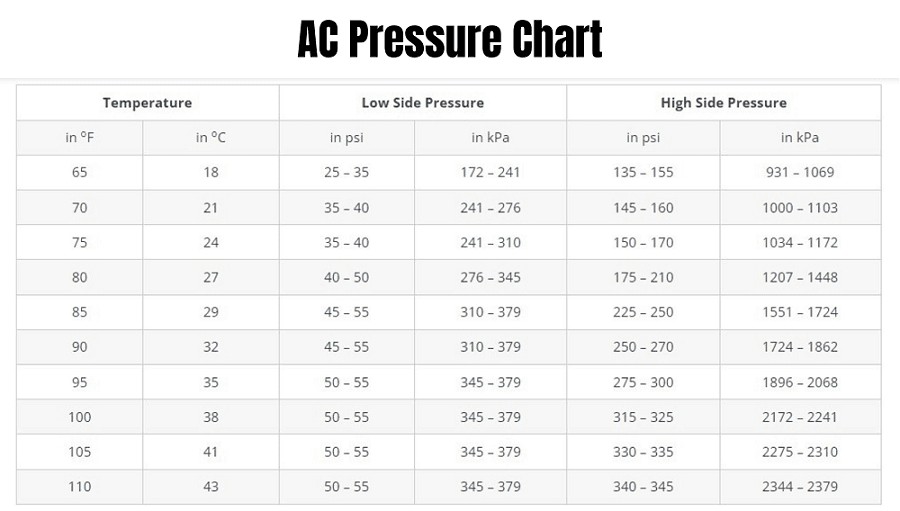

R134A A/C Pressure Troubleshooting Chart

The following a/c pressure chart provides typical high-side and low-side pressure readings for R134a refrigerant at different ambient temperatures. This chart is a valuable tool for diagnosing A/C system issues.

Alt: R134a AC pressure chart table showing normal low and high side pressure ranges at varying ambient temperatures.

Understanding Normal A/C Pressures with R-134A

Normal operating pressures for an R134a A/C system can fluctuate based on several factors, primarily ambient temperature, humidity, and the specific design of the A/C system. However, here are general guidelines for typical pressure ranges:

1. Low-Side Pressure (Suction Pressure):

- At approximately 65°F (18°C) ambient temperature: 25-35 psi

- At approximately 75°F (24°C) ambient temperature: 35-40 psi

- At approximately 85°F (29°C) ambient temperature: 45-50 psi

As ambient temperature rises, expect a slight increase in low-side pressure.

2. High-Side Pressure (Discharge Pressure):

- At approximately 65°F (18°C) ambient temperature: 135-155 psi

- At approximately 75°F (24°C) ambient temperature: 150-170 psi

- At approximately 85°F (29°C) ambient temperature: 225-250 psi

High-side pressure will increase more significantly with rising ambient temperatures.

General Automotive A/C Pressure Guidelines:

- Low-Side: 25 to 45 psi (varies with ambient temperature and system load)

- High-Side: 150 to 250 psi (varies with ambient temperature and system load)

General Residential/Commercial A/C Pressure Guidelines (Less Applicable to Automotive):

- Low-Side: 30 to 40 psi

- High-Side: 150 to 200 psi

Important: Always refer to the vehicle manufacturer’s specifications for the most accurate pressure ranges for your specific car model. These general values are a starting point for diagnostics. Measurements should be taken with the A/C system operating under normal conditions, and both low and high-side readings are essential for a complete system diagnosis.

How to Use the A/C Pressure Chart for Troubleshooting

If your car’s A/C isn’t cooling effectively, checking the refrigerant pressure is a crucial first step in diagnosis. An A/C technician will use a manifold gauge set to read the high-side and low-side pressures and compare them to the a/c pressure chart for R134a.

By analyzing the pressure readings in relation to the ambient temperature, you can begin to pinpoint potential problems. Here’s how to interpret pressure readings for troubleshooting:

| Condition | Low-Side Pressure | High-Side Pressure | Possible Cause |

|---|---|---|---|

| Normal | Within Chart Range | Within Chart Range | System likely operating correctly. |

| Low Low-Side & Low High-Side | Below Chart Range | Below Chart Range | Low Refrigerant Charge (Leak in system) |

| Low Low-Side & High High-Side | Below Chart Range | Above Chart Range | Restriction in liquid line, Expansion valve issue |

| High Low-Side & Low High-Side | Above Chart Range | Below Chart Range | Compressor inefficiency, Internal leak |

| High Low-Side & High High-Side | Above Chart Range | Above Chart Range | Overcharged System, Condenser airflow restriction |

Important Safety Note: Never vent R134a refrigerant into the atmosphere. It is illegal in many regions, including the U.S., due to its environmental impact. Refrigerant should always be recovered and recycled using proper equipment.

Conclusion

This guide has provided an overview of car A/C systems, the role of R134a refrigerant, and a practical a/c pressure chart for R134a. Regular maintenance, including checking refrigerant pressures, is key to ensuring the longevity and efficient operation of your car’s A/C system, preventing major repairs down the road. If you suspect issues with your A/C, consult a qualified technician to accurately diagnose and repair the problem. Understanding the a/c pressure chart is a valuable step in maintaining a comfortable driving experience.