From basic window wind-downs to sophisticated climate control, automotive air conditioning (AC) has revolutionized driving comfort. Modern car AC systems are intricate, comprising components like the compressor, condenser, evaporator, and refrigerant. Maintaining this complexity requires attention to detail, and one crucial aspect is monitoring the Ac System Pressure.

This article delves into the world of car AC refrigerant, providing an essential car AC pressure chart specifically for R134a, a widely used refrigerant. We will also equip you with troubleshooting knowledge related to ac system pressure to ensure your system operates efficiently.

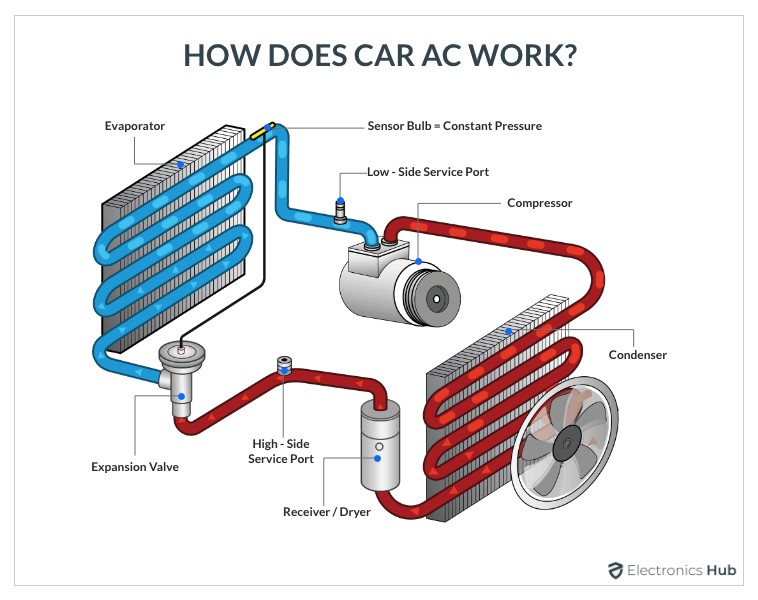

How Car AC Works: A Refrigeration Cycle Overview

Let’s begin with a fundamental understanding of car AC operation. Refrigeration, at its core, is the process of heat removal. In your car’s AC, unwanted heat from the cabin is mechanically transferred to the outside environment. Think of refrigerators and air conditioners as prime examples of this principle in action.

The magic ingredient in this heat transfer process is the refrigerant. This specialized fluid cycles continuously between a high-pressure liquid and a low-pressure gas state. During this transformation, it absorbs heat and moisture from inside your car, delivering cool, dry air in return.

Alt: Car AC system diagram showing compressor, condenser, expansion valve, evaporator, and refrigerant flow with pressure zones labeled.

The compressor, condenser, accumulator (or receiver drier), and evaporator work in perfect synchronization to produce that refreshing cool air. The refrigerant is the star player, absorbing heat at low pressure and temperature, converting from liquid to gas. To release the absorbed heat, it undergoes condensation from gas to liquid at high temperature and ac system pressure.

For effective and safe operation, a refrigerant must possess specific properties:

- Non-explosive and non-flammable for safety.

- Low boiling point for efficient heat absorption.

- Non-corrosive to prevent system damage and compatible with lubricants.

- Safe and non-toxic to minimize health risks.

- High latent heat value for maximum heat transfer capacity.

- Easily liquefiable and vaporizable at moderate pressures and temperatures.

Numerous refrigerants have been developed, each with varying properties. Some common and industry-approved options include:

- R-12 (historical)

- R-134a (widely used)

- Freon (various types like R-11, R-12, R-22)

- Freeze-12

- GHG-HP

- Hot Shot

- Ikon-12

- R-406A

R134a Refrigerant: The Industry Standard (For Now)

R-12, once prevalent in automotive and household refrigeration, was phased out due to its detrimental effects on the ozone layer, starting in 1994. R134a emerged as the replacement, becoming the standard in automotive AC systems and other refrigeration applications. Its thermodynamic properties are similar to R-12 but with a significantly reduced impact on ozone depletion.

R134a boils at -26.8°C at atmospheric pressure, and this boiling point increases to -10.6°C at 10 psi. If released at room temperature and atmospheric pressure, it instantly vaporizes. A critical aspect is the direct relationship between temperature and ac system pressure. For instance, R134a at 35psi (241kPa) will have a temperature of 4.4°C. This pressure-temperature relationship is fundamental to the condensation and expansion processes of R134a within the AC system.

Important Note: While R134a has been the standard, regulations are shifting again. Since 2012, HFO-1234yf is becoming the preferred refrigerant in new vehicles due to its even lower global warming potential. However, because a vast majority of vehicles still utilize R134a, this article and the ac system pressure chart will primarily focus on R134a.

Understanding R-134A Low Side and High Side Pressure

Why is monitoring ac system pressure so vital in your car’s AC? In a closed-loop automotive AC system, refrigerant constantly transitions between liquid and gas states, driven by pressure changes. This ac system pressure is directly linked to the refrigerant’s temperature.

Based on the refrigerant pressure at different points in the system, we categorize it into high side ac system pressure and low side ac system pressure.

Alt: Car AC pressure diagram highlighting low side pressure near the evaporator and high side pressure near the compressor and condenser.

The compressor initiates the cycle by receiving low-pressure gas from the evaporator. It compresses this gas, significantly increasing its pressure and temperature. The point immediately after the compressor is where high-pressure measurements are taken – the high side ac system pressure.

This high-pressure, hot gas then flows to the condenser. The condenser, often positioned near the radiator, uses airflow (sometimes aided by a fan) to cool the refrigerant. As it cools, the high-pressure gas condenses into a high-pressure liquid, releasing the heat it absorbed in the evaporator.

Next, the high-pressure liquid passes through the receiver/dryer. This component removes moisture and contaminants from the refrigerant. The filtered, high-pressure liquid then reaches the thermal expansion valve. Here, the high pressure is drastically reduced as the liquid expands, transforming into a low-pressure liquid.

This low-pressure liquid flows into the evaporator, typically located inside the car’s dashboard. As warm cabin air passes over the evaporator coils, the low-pressure liquid refrigerant absorbs heat and boils, turning into a low-pressure gas. This process cools the air, which is then blown into the car’s cabin. The low-pressure gas, now carrying heat from the cabin, returns to the compressor to repeat the cycle. The point after the evaporator, or just before the compressor, is where low-pressure measurements are taken – the low side ac system pressure.

Note: Service ports for pressure readings are strategically placed. The low side service port is often located just before the compressor, and the high side service port is usually positioned after the receiver/dryer in some systems.

R-134A AC Pressure Chart: A Diagnostic Tool

To accurately measure the low side and high side ac system pressure, technicians use a specialized manifold gauge set. This tool features two pressure gauges – one for the low side and one for the high side – integrated into a manifold assembly. Typically, the high side gauge and hose are red, while the low side counterparts are blue for easy identification.

Alt: AC manifold gauge set with red and blue hoses and gauges for high and low pressure readings, used for automotive AC system diagnosis.

R134A AC Pressure Troubleshooting Chart

The following chart provides typical high side and low side ac system pressure readings for R134a refrigerant at various ambient temperatures. This ac system pressure chart is a vital tool for diagnosing AC system performance.

Alt: R134a AC pressure chart table showing temperature in Fahrenheit and Celsius with corresponding low side and high side pressure ranges in PSI and kPa.

Normal AC Pressures Using R-134A: General Guidelines

Normal ac system pressure readings for an AC using R134a can fluctuate based on several factors, including ambient temperature, humidity, and the specific AC system design (automotive, residential, commercial). However, here are general guidelines for typical operating pressures:

1. Low-Side Pressure (Suction Pressure):

- At approximately 65°F (18°C) ambient temperature: 25-35 psi

- At approximately 75°F (24°C) ambient temperature: 35-40 psi

- At approximately 85°F (29°C) ambient temperature: 45-50 psi

Low-side pressure tends to increase slightly with rising ambient temperatures.

2. High-Side Pressure (Discharge Pressure):

- At approximately 65°F (18°C) ambient temperature: 135-155 psi

- At approximately 75°F (24°C) ambient temperature: 150-170 psi

- At approximately 85°F (29°C) ambient temperature: 225-250 psi

High-side pressure also increases significantly as ambient temperature rises.

Automotive AC Pressure: Typical Ranges

- Low-Side AC Pressure: 25 to 45 psi (variable with temperature and system load).

- High-Side AC Pressure: 150 to 250 psi (variable with temperature and system load).

Residential and Commercial AC Pressure: Typical Ranges

- Low-Side AC Pressure: 30 to 40 psi.

- High-Side AC Pressure: 150 to 200 psi.

Important Note: These are general guidelines. Always consult the manufacturer’s specifications for the specific AC system you are servicing. Pressure readings should be taken with the AC system running under normal operating conditions, and both low and high side pressures must be considered for a comprehensive system diagnosis.

How to Use the AC Pressure Chart for Troubleshooting

If your car AC isn’t cooling effectively, checking the ac system pressure is a crucial first step. An AC technician will use a manifold gauge set to measure the high and low side pressures and compare them against the R134a ac system pressure chart. Deviations from the normal ranges can indicate specific problems.

By analyzing the pressure readings in conjunction with the chart, you can begin to diagnose potential issues within the AC system. For example, abnormally low pressure on both sides might suggest a refrigerant leak, while excessively high pressure could indicate overcharging or a blockage in the system.

Caution: Never vent R134a refrigerant into the atmosphere. It is illegal in many regions, including the U.S., due to its environmental impact.

Conclusion: Maintaining Optimal AC System Pressure for Longevity

This article has provided an overview of car AC systems, R134a refrigerant, and the essential R134a ac system pressure chart. Proper maintenance, including regular checks of ac system pressure, is key to ensuring the long-term performance and reliability of your car’s AC system, minimizing the need for major repairs. It is recommended to periodically have your refrigerant levels checked by a qualified AC technician to ensure your system is operating within the optimal ac system pressure range.