Modern vehicles rely heavily on a network of sensors to ensure safety and optimal driving performance. Among these crucial components, the steering angle sensor (SAS) plays a pivotal role. This article, tailored for automotive professionals and enthusiasts at keyfobprog.com, delves into the critical importance of Calibration Steering Angle Sensor, why it’s necessary, and how to perform it correctly. Going beyond basic alignment procedures, we’ll explore why SAS calibration is indispensable for vehicle safety systems and accurate diagnostics.

Just because a wheel alignment machine indicates everything is within “green” tolerances, it doesn’t guarantee the steering angle sensor is reading zero degrees when the steering wheel is centered. This discrepancy can lead to a cascade of issues, affecting not only customer satisfaction and return visits but, more importantly, vehicle safety.

Integrating steering angle sensor reset and calibration into your standard alignment service is not just a value-added service; it’s a necessity for servicing contemporary vehicles. Automotive technology has advanced significantly, and our service procedures must evolve in tandem. Treating modern vehicles with outdated techniques is no longer sufficient.

While some systems might automatically calibrate, a significant number of vehicles necessitate manual calibration using a scan tool or alignment equipment with built-in calibration features. Given the diversity of vehicle systems, always consult the specific service information for the vehicle you are working on to ascertain the correct calibration procedure. Failing to adhere to manufacturer-specified procedures or overlooking crucial steps during system calibration is a common mistake. Many calibrations are multi-stage processes requiring meticulous attention to detail.

The Mercedes-Benz Calibration Example: A Step-by-Step Guide

Mercedes-Benz vehicles offer a prime illustration of the nuances in steering angle sensor calibration. The steering angle sensor in these vehicles is sophisticated enough to detect understeer by comparing the driver’s steering input with the vehicle’s actual trajectory.

Some older Mercedes-Benz models might seem to have a straightforward SAS calibration process: center the steering wheel, switch on the ignition, and perform a lock-to-lock steering maneuver, starting left, then right, and returning to center.

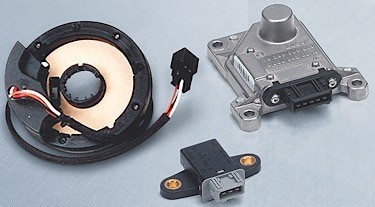

A steering angle sensor works with the yaw and accelerometer to determine what the vehicle is doing and what the driver wants the vehicle to do.

A steering angle sensor works with the yaw and accelerometer to determine what the vehicle is doing and what the driver wants the vehicle to do.

However, adhering to the correct Mercedes-Benz procedure often requires a comprehensive system calibration. This entails calibrating not only the steering angle sensor but also the yaw rate sensor, lateral accelerometer, and longitudinal accelerometer. This more intricate calibration is typically achieved using an adaptive drive function or a professional-grade factory or enhanced scan tool.

For Mercedes-Benz vehicles equipped with advanced driver-assistance systems (ADAS) such as adaptive cruise control, lane departure warning, and pre-collision braking, sensor calibration is not just recommended—it’s absolutely critical. Properly calibrated sensors are fundamental to the correct operation and reliability of these vital safety features.

Toyota Troubleshooting: Diagnosing Lost Steering Angles

Consider a scenario where a customer brings in a late-model Toyota complaining of unusual braking and steering sensations, especially during turns, accompanied by intermittent power loss. The customer mentions these issues began after a roadside assistance service replaced the vehicle’s battery.

A preliminary inspection and road test might reveal a braking system in good working order and proper stopping performance. The vehicle might also exhibit good straight-ahead tracking. However, the technician might notice a peculiar sensation – the car feels like it’s subtly steering itself, and engine power seems to fluctuate unexpectedly.

In such cases, a diagnostic scan is essential. It’s important to remember that not all system faults trigger diagnostic trouble codes (DTCs) within typical fault parameter ranges. Scanning for engine codes might yield no results to explain the power loss. However, examining live data might reveal an anomaly: the steering angle sensor reading -560 degrees even when the steering wheel is centered. How can this occur?

This situation can arise when the battery is replaced while the wheels are turned, for example, when a vehicle is parked in a tight space and needs to be moved to access the battery compartment. When power is restored, and the battery is reconnected with the wheels still turned, the steering angle sensor can erroneously establish this turned position as the new zero point.

Toyotas often utilize a “zero point calibration” reset procedure. Interestingly, on some Toyota models, the stability control module itself retains its calibration even when the battery is disconnected. However, the system can recalibrate based on the steering wheel’s position at the time of battery reconnection, inadvertently setting an incorrect zero reference.

A valuable diagnostic technique to pinpoint this issue is to use a scan tool to graph the stability system sensors – yaw rate sensor, steering angle sensor, lateral and longitudinal accelerometers – simultaneously. Performing this diagnostic step on a level surface (or ideally, on an alignment rack if perfectly level ground is unavailable) is crucial for accurate readings.

Conclusion: Elevating Service Standards with Steering Angle Sensor Calibration

Integrating steering angle sensor calibration into your service routine, especially during wheel alignments and after battery replacements, is more than just an added service—it’s a fundamental step towards ensuring vehicle safety and building customer trust. By embracing these advanced procedures, automotive service professionals can differentiate themselves, enhance service quality, and foster long-term customer relationships built on confidence and expertise. Prioritizing calibration steering angle sensor is not just about fixing cars; it’s about ensuring safety and driving confidence in the modern automotive landscape.