Seeing a check engine light illuminate on your dashboard can be concerning, especially when you’re unsure of the underlying issue. This is where a Dtc Scanner becomes an invaluable tool. Understanding Diagnostic Trouble Codes (DTCs) is crucial for identifying vehicle problems and taking prompt action. A DTC scanner, also known as an OBD-II scanner or engine code reader, empowers you to decipher these codes and gain insights into your vehicle’s health.

What Exactly is a DTC Code?

DTC stands for Diagnostic Trouble Code. In essence, it’s a standardized code used to pinpoint malfunctions within a vehicle or heavy equipment. While the check engine light signals a problem, the DTC code, read by a DTC scanner, specifies the nature and location of the fault. These codes are sometimes referred to as engine vehicle fault codes and are accessible through a diagnostic scan tool that connects to your vehicle’s port.

For vehicle owners and fleet managers alike, a basic grasp of DTCs and how to use a DTC scanner can be incredibly beneficial. Let’s delve deeper into DTCs, how they function, and how you can effectively read them using a DTC scanner.

The Origin of DTCs: Your Vehicle’s Diagnostic System

DTCs are generated by your vehicle’s On-Board Diagnostics (OBD) system. This system is constantly monitoring various vehicle components and systems. When it detects a fault, it not only triggers a warning light, like the check engine light, but also stores a corresponding DTC. The OBD system is the communication bridge that allows external devices, such as a DTC scanner, to interact with your vehicle’s computer.

Historically, OBD systems varied significantly between manufacturers, known as OBD-I. Today, we primarily use standardized systems for reading DTCs:

- OBD-II: The standard for most light- and medium-duty vehicles. A DTC scanner compatible with OBD-II is essential for these vehicles.

- J1939: The standard for heavy-duty vehicles and equipment. For trucks and heavy machinery, a DTC scanner that supports J1939 protocols is necessary.

The introduction of OBD-II brought about a universal DTC list, developed by the Society of Automotive Engineers (SAE). This standardization means a generic DTC scanner can read many codes across different makes and models.

However, it’s worth noting that manufacturer-specific DTCs still exist. While the standardized codes cover common issues, car manufacturers may add proprietary codes for more specific or complex problems. These manufacturer-specific codes can sometimes be harder to interpret without specialized tools or a mechanic’s expertise, but a capable DTC scanner can often still retrieve them.

OBD-II vs. J1939 Compliance: Which Scanner Do You Need?

OBD-II Compliance:

- Mandatory for cars and light trucks sold in the US after January 1, 1996. If you own a car from this era onwards, an OBD-II DTC scanner is likely what you need.

J1939 Compliance:

- Common in diesel engine vehicles and heavy equipment. For owners of diesel trucks, buses, or construction equipment, ensure your DTC scanner supports J1939.

- Industry standard for most heavy-duty trucks and buses.

If you’re unsure about your vehicle’s compliance, your vehicle manual, online resources, or a dealership can confirm whether you need an OBD-II or J1939 compatible DTC scanner.

Image alt text: A mechanic using a DTC scanner to diagnose a vehicle, highlighting the practical application of DTC scanners in automotive repair.

Image alt text: A mechanic using a DTC scanner to diagnose a vehicle, highlighting the practical application of DTC scanners in automotive repair.

Decoding OBD-II DTCs with Your Scanner

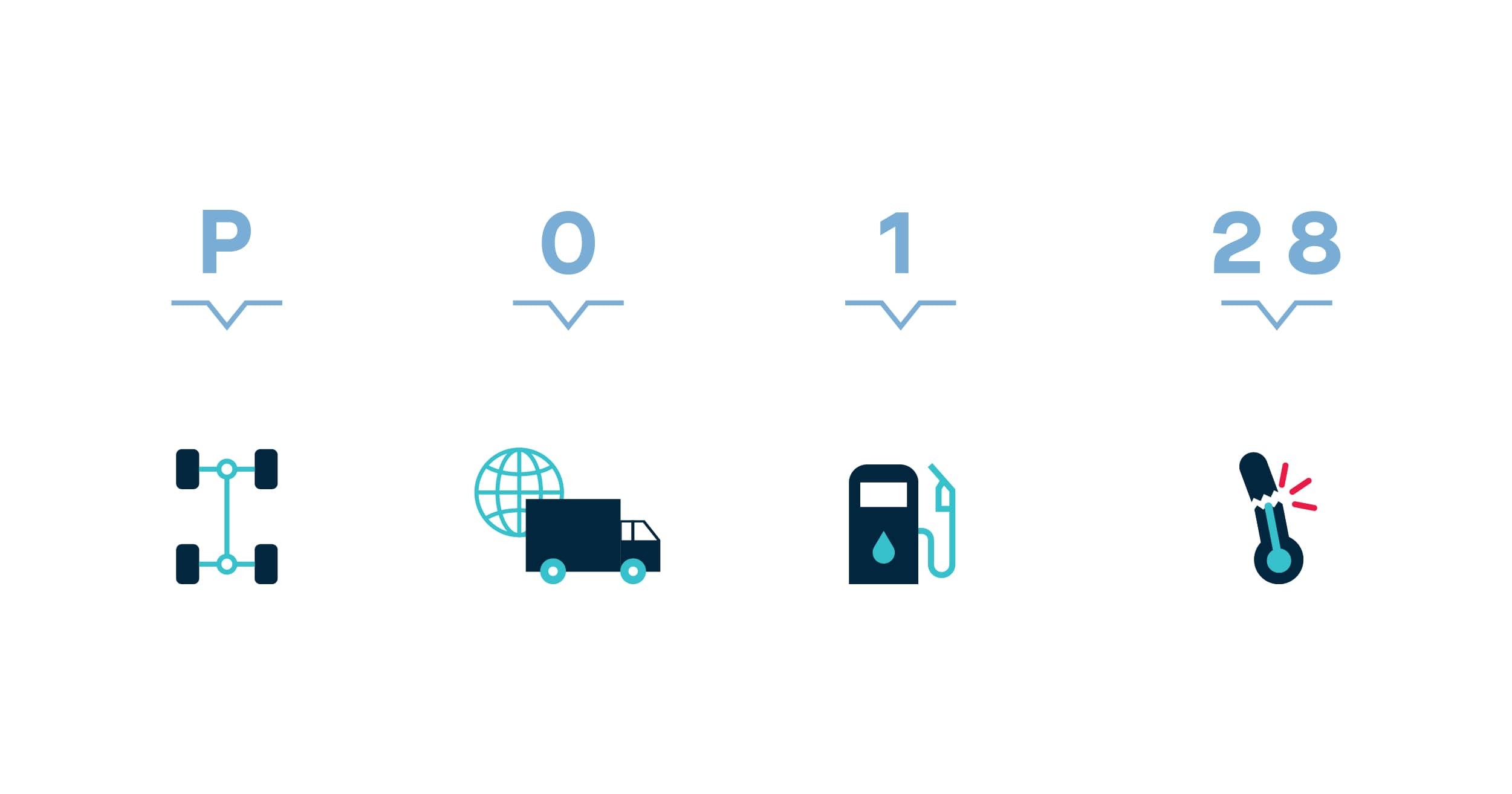

OBD-II DTCs are five characters long, and each character provides valuable diagnostic information when read by your DTC scanner.

The first character, always a letter, indicates the affected system:

- P (Powertrain): Engine, transmission, fuel system, and related components. Powertrain issues are frequently diagnosed using a DTC scanner.

- C (Chassis): Mechanical systems outside the passenger compartment like steering, suspension, and brakes. Chassis-related problems can also be identified with a DTC scanner.

- B (Body): Components primarily within the passenger compartment. Body-related DTCs can be less critical to immediate vehicle operation but still important to address, and a DTC scanner will pick them up.

- U (Network): Vehicle’s computer network and communication systems. Network issues can be complex, and a DTC scanner helps pinpoint communication faults.

The second character, a digit (0 or 1), reveals the code’s standardization:

- 0: Generic, standardized SAE code. These are universal codes that any OBD-II DTC scanner can read and interpret across different vehicle brands.

- 1: Manufacturer-specific code. These are unique to a particular car manufacturer and model. A more advanced DTC scanner may be needed to fully interpret these, or you might need manufacturer-specific resources.

- 2 or 3: Less common, manufacturer-specific in most cases, dependent on the first letter.

The third character, a digit from 1 to 8, specifies the subsystem at fault:

- 1: Fuel or air metering system. Issues here are common reasons to use a DTC scanner.

- 2: Fuel or air metering injection system.

- 3: Ignition system.

- 4: Emissions system. Emission problems are frequently flagged by DTCs and diagnosed with a DTC scanner.

- 5: Vehicle speed controls and idle control system.

- 6: Computer output circuit.

- 7 & 8: Transmission-related issues.

The fourth and fifth characters, a two-digit number (0-99), are the specific fault index. They pinpoint the exact nature of the problem. Your DTC scanner will display this code, and you can then look up its meaning.

If you’re uncertain about a code’s meaning after using your DTC scanner, consult your vehicle manual or manufacturer resources for detailed explanations.

Image alt text: Scalable cloud application, representing the data processing and accessibility of DTC information through modern DTC scanners and telematics systems.

Interpreting DTCs: An Example with Your DTC Scanner

Each DTC corresponds to a specific vehicle malfunction. Take the common DTC P0128, easily read by any standard DTC scanner:

- P: Powertrain issue.

- 0: Generic SAE code.

- 1: Fuel and air metering subsystem.

- 28: Specific fault index.

Putting it together, P0128 indicates an issue with the engine coolant temperature being below the thermostat regulating temperature. Your DTC scanner provides the code, and understanding the structure helps you interpret it, or quickly look up the specific meaning.

Common DTCs Encountered with a DTC Scanner

Some DTCs are more frequently encountered. Here are a few common ones that your DTC scanner might pick up:

- P0442: Small evaporative emission control system leak.

- P0606: Powertrain Control Module (PCM) or Engine Control Module (ECM) malfunction.

- P0101: Mass Air Flow (MAF) sensor or circuit fault.

- P0110: Intake Air Temperature sensor circuit malfunction.

- P0500: Vehicle Speed Sensor malfunction.

- P0706: Transmission Range Sensor circuit range fault.

While a DTC scanner is excellent for identifying malfunctions, remember it doesn’t pinpoint the cause. Further diagnosis by a mechanic is often necessary to address the root cause of the issue flagged by the DTC.

Reading J1939 DTCs with a Compatible Scanner

A J1939 DTC, read by a J1939-compatible DTC scanner, contains four key fields:

- Suspect Parameter Number (SPN): The specific parameter with the error.

- Failure Mode Identifier (FMI): The type of error (e.g., range violation, short circuit, calibration error).

- Occurrence Counter (OC): Counts error occurrences, even when inactive.

- SPN Conversion Method (CM): Defines byte alignment within the DTC.

DTC Scan Tools for Efficient Fleet Management

While basic OBD-II DTC scanners are readily available, fleet managers overseeing numerous vehicles need more efficient solutions. Manually checking each vehicle with a DTC scanner is time-consuming.

Telematics solutions, like Samsara, offer integrated maintenance tools that streamline DTC identification. Samsara vehicle gateways plug into the OBD-II or J1939 port, automatically sending vehicle data, including DTCs, to the cloud. This means DTCs are instantly visible on a dashboard, and alerts can be set up for immediate notifications. Instead of physically using a DTC scanner on every vehicle, fleet managers get real-time DTC information remotely.

For fleets experiencing multiple DTC issues, a telematics system with DTC tools drastically speeds up issue identification and allows for proactive maintenance scheduling. This is a significant advantage over traditional manual DTC scanner checks.

Telematics: Simplifying DTC Understanding

Seeing a check engine light no longer needs to be a mystery. With telematics solutions like Samsara, understanding DTCs becomes straightforward. Instead of relying solely on manual DTC scanners, fleet managers and vehicle owners can leverage technology for efficient diagnostics.

Samsara vehicle gateways act as advanced DTC scanners, relaying information directly to a user-friendly dashboard. Vehicle fault alerts can be customized to notify you of specific DTCs that are critical for your fleet. Samsara’s DTC filtering further refines alerts, ensuring you focus on the most important issues.

To learn more about simplifying DTC management with telematics, explore Samsara’s fleet maintenance solutions or sign up for a free trial. Embrace the power of modern DTC scanner technology integrated into telematics for proactive vehicle maintenance.