Seeing your check engine light illuminate can be unsettling, especially without knowing the underlying issue. Diagnostic Trouble Codes, or DTCs, are the key to understanding what’s going wrong with your vehicle. As a vital part of modern vehicle diagnostics, DTCs provide valuable insights into malfunctions, allowing for timely and effective repairs.

This guide will delve into the world of DTCs, explaining what they are, where they come from, how to interpret them, and how they can be efficiently managed using modern telematics solutions. Whether you’re a car owner, fleet manager, or automotive enthusiast, understanding DTCs is crucial for maintaining vehicle health and performance.

What Exactly are DTCs?

DTC stands for Diagnostic Trouble Code. Essentially, a DTC is a standardized code generated by your vehicle’s onboard computer system to report a detected fault or malfunction. While the check engine light is a general warning signal, a DTC is a specific identifier that pinpoints the area and nature of the problem. You might also hear DTCs referred to as vehicle fault codes or engine fault codes. These codes can be accessed using diagnostic scanners that connect to your vehicle’s diagnostic port.

For drivers and fleet managers alike, a basic grasp of DTCs can significantly improve vehicle maintenance and reduce downtime. Let’s explore the origins and workings of these essential diagnostic tools.

The Origin and Evolution of DTCs: From OBD-I to Modern Standards

DTCs are a product of the vehicle’s On-Board Diagnostics (OBD) system. The OBD system continuously monitors various vehicle systems and generates DTCs when it detects a problem. This system not only diagnoses faults but also alerts drivers through the check engine light and allows external devices like OBD scanners to communicate with the vehicle’s computer.

In the early days of vehicle diagnostics, known as OBD-I, standards were inconsistent and varied greatly between manufacturers. However, with the introduction of OBD-II, the automotive industry moved towards standardization. Today, two primary standards are used for reading DTCs:

- OBD-II: The standard for light-duty and medium-duty vehicles.

- J1939: The standard for heavy-duty vehicles and equipment.

The Society of Automotive Engineers (SAE) played a crucial role in developing OBD-II and creating a standardized list of DTCs common across all manufacturers. This standardization significantly simplified vehicle diagnostics.

While OBD-II provides a wide range of universal DTCs, it’s important to note that some manufacturers still utilize manufacturer-specific DTCs to address unique vehicle complexities. These codes, however, often require specialized knowledge or mechanic expertise to interpret accurately.

OBD-II and J1939 Compliance: Knowing Your Vehicle’s Standard

Understanding whether your vehicle is OBD-II or J1939 compliant is the first step in effective DTC management. Here’s a general guideline:

OBD-II Compliance:

- Mandatory for all cars and light trucks sold in the United States after January 1, 1996.

J1939 Compliance:

- Typically found in most diesel engine vehicles and heavy equipment.

- Industry standard for most heavy-duty trucks and buses.

If you are unsure about your vehicle’s compliance, the vehicle’s owner manual, online resources, or your dealership can provide definitive confirmation.

OBD II Port and Cable

OBD II Port and Cable

Decoding OBD-II DTCs: Understanding the Five Characters

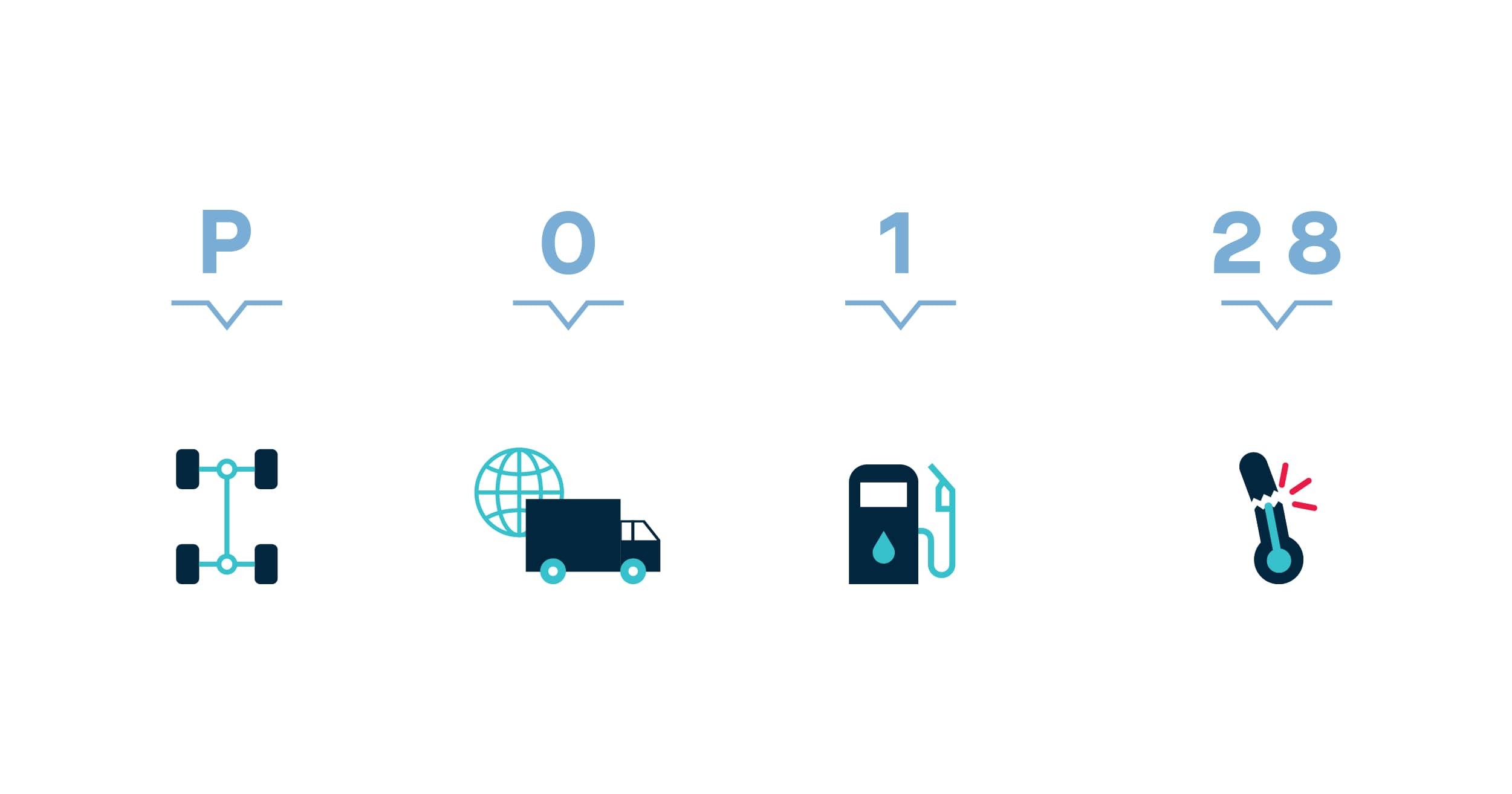

OBD-II DTCs are composed of five characters, each providing specific information about the vehicle’s malfunction. Let’s break down the structure:

-

First Character (Letter): System Designation

- P (Powertrain): Relates to the engine, transmission, fuel system, and associated components.

- C (Chassis): Indicates issues with mechanical systems outside the passenger compartment, such as steering, suspension, and brakes.

- B (Body): Points to problems within the passenger compartment, including parts like power windows or airbags.

- U (Network): Signifies issues with the vehicle’s onboard computer network and communication systems.

-

Second Character (Digit): Code Type

- 0: Indicates a generic, standardized SAE code, common to all OBD-II compliant vehicles.

- 1: Denotes a manufacturer-specific code, unique to a particular car make or model and often less common.

- 2 or 3: Less frequent, typically manufacturer-specific, but their meaning depends on the first letter of the code.

-

Third Character (Digit 1-8): Subsystem at Fault

- 1: Fuel or air metering system.

- 2: Fuel or air metering injection system.

- 3: Ignition system.

- 4: Emissions system.

- 5: Vehicle speed controls and idle control system.

- 6: Computer output circuit.

- 7 & 8: Transmission-related issues.

-

Fourth and Fifth Characters (Digits 0-99): Specific Fault Index

- These two digits, read together as a number from 0 to 99, pinpoint the exact nature of the vehicle problem within the identified subsystem.

If you are unsure about the meaning of a specific DTC, always refer to your vehicle’s manufacturer documentation or consult a repair manual for detailed explanations.

Interpreting DTCs: A Practical Example with P0128

Let’s take a common DTC example, P0128, to illustrate how to interpret these codes:

- P: Powertrain – The issue is related to the engine, transmission, or related systems.

- 0: Generic Code – This is a standardized code, not manufacturer-specific.

- 1: Fuel and Air Metering Subsystem – The problem is within this specific subsystem.

- 28: Specific Fault Index – This index, in combination with the preceding characters, defines the exact problem.

Putting it together, DTC P0128 typically indicates “Coolant Thermostat Below Coolant Regulating Temperature.” This detailed breakdown shows how DTCs move beyond a simple warning light to provide actionable diagnostic information.

Common DTCs and What They Indicate

While there are thousands of possible DTCs, some are more commonly encountered than others. Here are a few examples of common DTCs and their meanings:

- P0442: Evaporative Emission Control System Leak Detected (small leak). This often indicates a problem with the fuel cap or EVAP system components.

- P0606: PCM/ECM Processor Fault. This points to a malfunction within the Powertrain Control Module (PCM) or Engine Control Module (ECM), the vehicle’s main computer.

- P0101: Mass Air Flow (MAF) Sensor Circuit Range/Performance Problem. This suggests an issue with the MAF sensor, which measures the air entering the engine.

- P0110: Intake Air Temperature Sensor Circuit Malfunction. Indicates a problem with the sensor that measures the temperature of the air entering the engine.

- P0500: Vehicle Speed Sensor Malfunction. Signifies an issue with the sensor that measures vehicle speed.

- P0706: Transmission Range Sensor Circuit Range/Performance. Points to a problem with the sensor that detects the transmission gear position.

It’s crucial to remember that while DTCs identify a malfunction, they don’t always reveal the root cause. Further diagnosis by a qualified mechanic is often necessary to pinpoint and fix the underlying issue.

Understanding J1939 DTCs: Heavy-Duty Vehicle Diagnostics

J1939 DTCs, used in heavy-duty vehicles, have a different structure compared to OBD-II codes. A J1939 DTC comprises four fields:

- Suspect Parameter Number (SPN): This number identifies the specific component or system (parameter) that is experiencing the fault. Each SPN corresponds to a defined vehicle parameter.

- Failure Mode Identifier (FMI): The FMI describes the type of error that has occurred. Examples include value range violations (high or low readings), sensor short circuits, incorrect data update rates, or calibration errors.

- Occurrence Counter (OC): This counter tracks how many times the error condition has occurred for a specific SPN. It retains this count even if the error is no longer actively present.

- SPN Conversion Method (CM): The CM defines the byte alignment within the DTC message. A value of “0” represents a standard structure, while other values might indicate different, system-specific methods.

While J1939 DTCs are more complex, they provide detailed diagnostic information crucial for maintaining heavy-duty vehicles and equipment.

Streamlining DTC Management with Telematics Solutions

While OBD-II scanners are readily available, manually checking each vehicle for DTCs can be inefficient, especially for fleet managers overseeing numerous vehicles. This is where telematics solutions offer a significant advantage.

Fleet management solutions like Samsara incorporate maintenance tools that simplify DTC identification and management. Samsara vehicle gateways plug directly into a vehicle’s OBD-II or J1939 port and transmit vehicle data, including DTCs, to a cloud-based dashboard in real-time.

This means that when a DTC is generated, it automatically appears in your Samsara Dashboard, and you can even set up alerts to be notified immediately. In situations where multiple fleet vehicles experience DTC issues, telematics solutions enable rapid identification of the problems, facilitating quick maintenance scheduling and minimizing vehicle downtime.

Conclusion: DTCs and Telematics – Empowering Vehicle Maintenance

Understanding DTCs is no longer just for mechanics; it’s valuable knowledge for any vehicle owner or fleet operator. DTCs provide the crucial link between a warning light and actionable diagnostic information, enabling informed decisions about vehicle maintenance and repair.

Telematics solutions further amplify the power of DTCs by providing efficient, real-time DTC monitoring and management. By leveraging tools like Samsara, you can proactively address vehicle issues, reduce downtime, and optimize vehicle performance. Embrace the power of DTCs and telematics to take control of your vehicle diagnostics and ensure vehicle longevity and reliability.

To learn more about how telematics can simplify DTC management and vehicle maintenance, explore Samsara’s fleet maintenance solutions or sign up for a free trial today.