Modern vehicles are marvels of engineering, meticulously designed to optimize performance and efficiency. At the heart of this optimization lies the engine control module (ECM), which constantly monitors and adjusts the air-fuel mixture for ideal combustion. Two key sensors provide crucial data to the ECM: the Mass Airflow (MAF) sensor, measuring incoming air, and the oxygen sensor, analyzing exhaust byproducts. These sensors work in concert to ensure your engine operates cleanly and efficiently through a process called fuel trim.

Carburetors, found in older vehicles, had limited fuel trim capabilities, relying on fixed jets and chokes for adjustments. However, today’s fuel-injected engines boast sophisticated Fuel Trim Systems capable of dynamic compensation. For instance, a clogged air filter restricts airflow, mimicking a choked carburetor. While a carburetor would struggle, a fuel-injected engine detects the reduced oxygen and compensates by leaning out the fuel mixture. This adjustment, known as negative fuel trim, reduces power but maintains engine operation. Conversely, if unmetered air enters the system, the oxygen sensor detects a lean condition, prompting the ECM to enrich the mixture with positive fuel trim.

However, the ECM’s ability to compensate is not limitless. When the fuel trim adjustments reach their maximum range, it signals an underlying issue, often triggering diagnostic trouble codes related to rich or lean conditions. Even minor imbalances, such as a slightly restricted air filter, can negatively impact fuel trim, diminishing both power and fuel economy, even if no error codes are immediately present. Replacing a neglected air filter and resetting the fuel trims can often restore optimal engine performance.

Decoding Fuel Trims: Short-Term and Long-Term Adjustments

Fuel trim is essentially the real-time adjustment the ECM makes to the fuel delivery system to maintain the ideal stoichiometric air-fuel ratio. This ratio, approximately 14.7:1 for gasoline engines, ensures the most efficient and complete combustion. Fuel trim values are expressed as percentages, indicating how much fuel is being added or subtracted relative to a baseline.

- Positive Fuel Trim: A positive percentage signifies that the ECM is adding fuel by increasing the duration (pulse width) of the fuel injector signal. This enrichment is a correction for a lean condition, meaning too much air or not enough fuel is initially present.

- Negative Fuel Trim: Conversely, a negative percentage indicates that the ECM is reducing fuel by shortening the injector pulse width. This leaning of the mixture compensates for a rich condition, where there is too much fuel or not enough air.

While a slightly richer mixture can sometimes enhance power, it comes at the cost of increased fuel consumption and higher emissions. Conversely, an excessively lean mixture, while fuel-efficient, can lead to misfires and increased emissions if combustion becomes unstable. Accurate oxygen sensor feedback is paramount for effective fuel trim. Without a reliable signal, the ECM cannot accurately determine the air-fuel ratio and make necessary corrections.

Fuel trim values are not erased when the engine is turned off. They are stored in the ECM’s memory, allowing the system to adapt and learn over time. This learned adaptation ensures smoother and more efficient operation across various driving conditions. However, clearing the ECM’s memory, either with a scan tool or by disconnecting the battery, will reset fuel trim values, forcing the system to relearn its adjustments from scratch.

Reading Fuel Trim Values with a Scan Tool

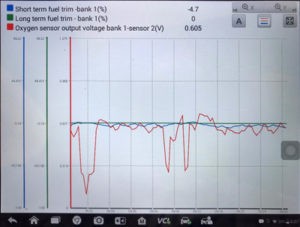

To diagnose potential fuel trim issues, you’ll need to access live engine data using an OBD-II scan tool. Navigate to the live data or PIDs (Parameter IDs) section of your scan tool. You will typically find two fuel trim parameters: Short-Term Fuel Trim (STFT) and Long-Term Fuel Trim (LTFT).

- Short-Term Fuel Trim (STFT): STFT values are dynamic and fluctuate rapidly in response to immediate changes in engine load, throttle position, and operating conditions. Expect to see STFT values swing considerably, potentially by +/- 25% or more, as the ECM makes real-time adjustments.

- Long-Term Fuel Trim (LTFT): LTFT represents a longer-term average of fuel trim corrections. It reflects the ECM’s learned adjustments over time to compensate for more persistent deviations in the air-fuel ratio. Ideally, LTFT values should remain within a range of -10% to +10%. LTFT provides a more stable and indicative reading of the overall health of the fuel trim system.

It’s crucial to understand that fuel trim values are not instantaneous reactions but rather corrective actions based on sensor feedback. The ECM constantly measures, reacts, and corrects to maintain optimal fuel trim. If you observe consistently high positive or negative fuel trim values, especially if they are pegged at maximum limits, it indicates a potential problem. Common culprits include intake manifold leaks (leading to lean conditions and positive trim) or faulty fuel injectors stuck open (causing rich conditions and negative trim). Fuel trims are invaluable diagnostic indicators but should be considered a starting point for further investigation, not the definitive answer.

Air Filters and Their Impact on Fuel Trim

Air filters play a significant role in maintaining proper fuel trim. A clogged or excessively restrictive air filter reduces airflow into the engine. The MAF sensor registers less air, and the ECM, in turn, reduces fuel delivery, resulting in negative fuel trim. This negative trim is the engine’s attempt to compensate for the perceived rich condition caused by the lack of air.

Conversely, diagnosing positive fuel trim related to air filter issues is less direct. While it’s less common, a positive fuel trim could theoretically occur if an aftermarket air intake system allows significantly more airflow than the stock system. This increased airflow might cause the oxygen sensor to detect a lean condition, prompting the ECM to add fuel and create positive fuel trim. However, positive fuel trim is more frequently associated with issues introducing unmetered air into the system after the MAF sensor, such as vacuum leaks, rather than over-performing air filters.

In conclusion, understanding your vehicle’s fuel trim system is essential for diagnosing engine performance and efficiency issues. By monitoring fuel trim values, especially STFT and LTFT, and considering factors like air filter condition, you can gain valuable insights into the health of your engine’s fuel management system and address potential problems proactively.