Understanding your vehicle’s health is becoming increasingly accessible thanks to On-Board Diagnostics (OBD) systems. These systems monitor various parameters of your car, and accessing this data can be invaluable for diagnostics and performance analysis. This guide will walk you through the basics of obtaining Obd Readings using an Arduino microcontroller and the MCP2515 CAN controller, specifically focusing on retrieving engine speed data using PID (Parameter ID) 0C.

One of the most useful aspects of OBD-II is the standardized set of PIDs that allow you to request specific data points from your vehicle’s computer. PID 0C is designated for “Engine speed,” providing real-time information about your engine’s revolutions per minute (RPM). Let’s explore how to request and interpret this crucial OBD reading.

To get started, you’ll need an Arduino, an MCP2515 CAN bus module, and the necessary wiring to connect to your vehicle’s OBD-II port. The following code snippet provides a foundation for requesting PID 0C and displaying the raw CAN bus traffic.

This code initializes the MCP2515 CAN controller, sets up filters (which you may need to adjust based on your vehicle’s specific CAN IDs), and then enters a loop. Within the loop, it checks for incoming CAN messages and prints them to the serial monitor. Every second, it sends a CAN message requesting PID 0C.

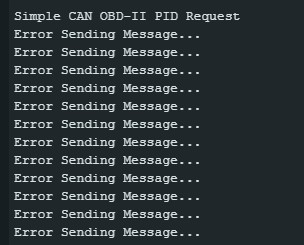

After uploading this code to your Arduino and connecting it to your car’s OBD-II port, you should see a stream of CAN bus data in the serial monitor. However, directly interpreting this raw data as RPM might be misleading.

Serial output showing raw CAN data

Serial output showing raw CAN data

The image above shows an example of the serial output. You can see “Extended ID” or “Standard ID” followed by the data received. To get the actual engine speed from these OBD readings, you need to understand how PID 0C data is encoded.

Interpreting Engine Speed (PID 0C) Data:

According to the OBD-II standard for PID 0C, the engine speed is returned in two bytes.

- Byte A: Most significant byte

- Byte B: Least significant byte

The formula to calculate RPM is:

*RPM = ((A 256) + B) / 4**

Therefore, you’ll need to modify the code to extract these two bytes from the rxBuf array when a response to your PID 0C request is received and apply this formula. You’ll also need to identify the specific CAN ID that your vehicle uses to respond to OBD-II requests. Functional addressing (using FUNCTIONAL_ID) is often used, but some vehicles might require specific target addresses.

Troubleshooting and Further Exploration of OBD Readings:

If you’re not getting the expected OBD readings or engine speed values, consider these troubleshooting steps:

- Verify CAN Bus Connection: Double-check your wiring between the MCP2515 module, Arduino, and OBD-II port. CAN bus communication is sensitive to wiring issues.

- Vehicle Compatibility: Ensure your vehicle fully supports OBD-II and PID 0C. While most modern vehicles do, there can be exceptions. Consult your vehicle’s service manual or online resources for compatibility information.

- CAN ID Filtering: The provided code includes example filters. You might need to adjust these filters or even remove them initially to see all CAN traffic and identify the correct response IDs for your vehicle. Tools like a CAN bus analyzer can be helpful for this.

- Data Interpretation: Carefully examine the received data. Ensure you are correctly identifying the response to your PID 0C request and extracting the correct bytes for engine speed calculation. The response often contains a service byte and the PID itself before the data bytes.

- Baud Rate and Clock Speed: Double-check that the baud rate in your code (500kbps in this example) and the MCP2515 clock speed (8MHz) are correctly configured for your hardware and vehicle.

By systematically analyzing your OBD readings and troubleshooting potential issues, you can successfully retrieve valuable data from your vehicle’s OBD-II system using Arduino and gain deeper insights into its operation. This is just the beginning – the world of OBD-II offers a wealth of information waiting to be explored!