The error code P164d00, often displayed in vehicle diagnostic systems, indicates an issue with the reduced oil pressure switch. This code, while seemingly straightforward, can be a starting point for diagnosing potentially serious engine oil pressure problems. Let’s break down what P164D00 means and how to approach troubleshooting it, drawing from real-world experiences in automotive repair.

The P164D code itself points to the “Reduced Oil Pressure Switch Circuit,” and the “00” suffix typically signifies a malfunction within this system. However, it’s crucial to avoid immediately assuming a mechanical oil pressure failure. The fault could very well lie within the electrical components of the switch or sensor system.

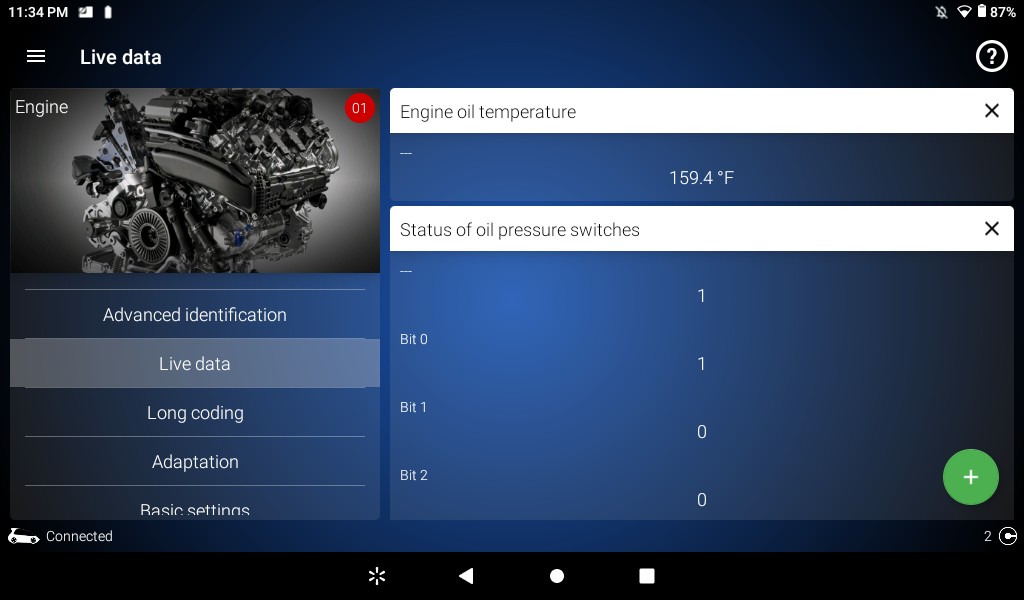

A logical first step in diagnosing a P164D00 code is to investigate the electrical aspects of the oil pressure switch. Modern vehicles often use sophisticated sensor systems that provide nuanced data. In many systems, the oil pressure switch status is represented by a binary value. For instance, in some implementations, a 2-bit binary system is used where:

- 0: Indicates a fault or abnormal reading.

- 1: Represents normal oil pressure at idle, once the engine is warm.

- 3: Shows normal pressure during cold starts and when engine RPM exceeds a certain threshold (e.g., 3500 RPM).

- 2: This value is particularly interesting as it suggests a conflict – the primary oil pressure switch indicates good pressure (high range), while the reduced oil pressure switch signals low pressure. This discrepancy often points to an electrical malfunction rather than actual low oil pressure.

To get real-time data, using an OBD-II scan tool with live data monitoring capabilities is invaluable. By observing the oil switch status, you can gain insights into what the car’s computer is seeing.

For example, consider a case where live data was monitored on a vehicle exhibiting a P164D00 code. Initially, after the engine warmed up, bit 0 (reduced oil pressure switch) read as ‘1’, which seemed normal.

However, further monitoring revealed a concerning shift. Just minutes later, all values dropped to zero, coinciding with the oil pressure warning light illuminating on the dashboard.

Alongside electrical diagnostics, a mechanical oil pressure test is essential to verify if the readings are accurate. A simple, inexpensive oil pressure gauge can provide crucial data. In the same case, a physical oil pressure test revealed alarming results:

- Cold start: Around 35 psi (pounds per square inch).

- Warmed up/Idle: Dropped significantly below 10 psi, possibly as low as 3-4 psi.

- Cruising: Stabilized around 15 psi.

- Higher RPMs: Increased to 35-40 psi, then gradually decreased back to 15 psi.

- Stoplights/Idle after driving: Oil pressure would again fall below 10 psi.

While investigating oil pressure issues, it’s also beneficial to check related engine parameters. In this scenario, the camshaft position was also monitored and found to be within the expected range, fluctuating between 27 and 28 degrees.

Conclusion

The P164D00 code is a vital indicator that requires a systematic approach to diagnosis. While it points to the reduced oil pressure switch, a comprehensive troubleshooting process should include:

- Electrical System Check: Use an OBD-II scanner to monitor live data from the oil pressure switch and sensor system. Look for unusual readings or inconsistencies.

- Mechanical Oil Pressure Test: Employ a physical oil pressure gauge to accurately measure the engine’s oil pressure under various conditions (cold start, warm idle, cruising, and higher RPMs).

- Contextual Data Review: Examine related engine parameters like camshaft position to ensure a holistic understanding of the engine’s condition.

By combining electrical checks with mechanical testing, you can effectively diagnose the root cause behind a P164D00 code, whether it’s an electrical glitch or a genuine low oil pressure issue, and take appropriate corrective action. Ignoring this code can lead to serious engine damage, so prompt and thorough diagnosis is crucial.