Modern vehicles are marvels of engineering, constantly monitoring and adjusting themselves for optimal performance and efficiency. Central to this process is the concept of fuel trims. If you’re involved in automotive repair, or simply a car enthusiast wanting to understand your vehicle better, grasping what fuel trims are and how they work is crucial. This article will delve into fuel trims, explaining their function and how they relate to your engine’s health.

The Role of Sensors in Fuel Management

To understand fuel trims, we first need to appreciate the sensors that make them possible. Modern engines are equipped with sophisticated sensors, primarily the Mass Airflow (MAF) sensor and oxygen (O2) sensors, to meticulously measure engine performance.

The Mass Airflow (MAF) sensor measures the amount of air entering the engine. This is a critical piece of information for the engine control module (ECM) or powertrain control module (PCM), often referred to as the engine computer.

Oxygen (O2) sensors, located in the exhaust system, analyze the byproducts of combustion. They detect the amount of oxygen present in the exhaust gases, providing feedback on the efficiency of the combustion process.

These two sensors work in tandem, providing the engine computer with the data it needs to optimize the air-fuel mixture. The goal is to achieve the most efficient and cleanest combustion possible.

Fuel Trims Defined: Fine-Tuning the Air-Fuel Ratio

Fuel trim is the engine computer’s dynamic adjustment to the air-fuel mixture. Think of it as the fine-tuning mechanism that ensures your engine receives the ideal ratio of air to fuel for combustion. Carburetors, in older vehicles, had limited fuel trim capabilities due to their fixed jets. They relied on chokes for cold starts to richen the fuel mixture by restricting air intake. However, modern fuel-injected engines can compensate for various conditions through fuel trims.

The engine computer constantly analyzes the signals from the MAF and O2 sensors. Based on this data, it makes real-time adjustments to the amount of fuel injected into the cylinders. This adjustment is fuel trim.

- Positive Fuel Trim: A positive fuel trim value indicates that the engine computer is adding fuel. This means the oxygen sensor is detecting a lean condition (too much oxygen in the exhaust), and the computer is compensating by increasing the injector pulse width, allowing more fuel into the combustion chamber.

- Negative Fuel Trim: Conversely, a negative fuel trim signifies that the engine computer is reducing fuel. This happens when the oxygen sensor detects a rich condition (too little oxygen in the exhaust). The computer then decreases the injector pulse width, reducing the amount of fuel injected.

This continuous adjustment ensures the engine maintains a balanced air-fuel ratio for efficient operation. An excessively rich mixture can boost power (to a certain extent) but increases fuel consumption and emissions. A very lean mixture, while improving fuel economy, can lead to misfires and increased emissions if it’s too lean to ignite properly.

Accurate fuel trim values depend on a reliable signal from the oxygen sensor. If the O2 sensor is faulty, the engine computer receives incorrect feedback and cannot make appropriate fuel adjustments. Fuel trim values are stored in the computer’s memory even after the engine is turned off. This allows the system to continue learning and adapting upon restarting. However, clearing the computer’s memory, either with a scan tool or by disconnecting the battery, will reset these values, forcing the computer to relearn the fuel adjustments.

Reading Fuel Trims: Short-Term and Long-Term

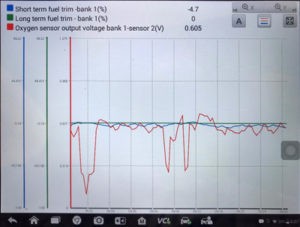

To diagnose engine performance issues related to fuel trim, technicians use scan tools to read live engine data. Within this data, you’ll typically find two types of fuel trim values: Short-Term Fuel Trim (STFT) and Long-Term Fuel Trim (LTFT).

Short-Term Fuel Trim (STFT) values are dynamic and fluctuate rapidly. They reflect the engine computer’s immediate adjustments in response to changing conditions like engine load, speed, and temperature. STFT values can change significantly and quickly, often bouncing around as much as 25% or more in either direction.

Alt text: A scan tool displaying live engine data, highlighting Short-Term Fuel Trim (STFT) values fluctuating in real-time.

Long-Term Fuel Trim (LTFT) provides a more stable, averaged view of fuel adjustments over time. It represents the cumulative corrections the engine computer has made to maintain the ideal air-fuel ratio. LTFT values typically range from -10% to +10% under normal operating conditions. LTFT is a better indicator of underlying issues affecting the fuel mixture.

Alt text: A scan tool interface showing Long-Term Fuel Trim (LTFT) values, indicating a more averaged fuel correction over a longer period.

Observing both STFT and LTFT is essential for understanding the overall fuel trim strategy. The engine computer doesn’t react instantaneously; it reacts, corrects, and then measures the result, continuously refining the fuel trim.

If fuel trim values are consistently pegged at their maximum positive or negative limits, it signals a problem. This could indicate issues such as intake manifold leaks (causing lean conditions and high positive fuel trims) or a stuck-open fuel injector (leading to rich conditions and high negative fuel trims). Fuel trims serve as a valuable starting point for diagnosing engine problems, not the definitive answer.

Air Filters and Their Impact on Fuel Trims

The condition of your air filter directly impacts fuel trims. A clogged or restrictive air filter reduces the amount of air entering the engine. The MAF sensor detects less airflow, and the oxygen sensor may initially sense a rich condition (less oxygen in exhaust due to less air entering). In response, the engine computer will command a negative fuel trim, reducing fuel injection to lean out the mixture and compensate for the restricted airflow.

Conversely, a very clean or high-flow air filter, or issues in the air induction system allowing excessive unmetered air, can lead to a lean condition. In this scenario, the oxygen sensor detects excess oxygen, and the engine computer will increase fuel injection, resulting in a positive fuel trim.

Understanding the relationship between air filters and fuel trims is crucial for diagnosing performance and efficiency issues. While a slightly restricted air filter might not trigger a check engine light immediately, the compromised fuel trim can negatively impact power and fuel economy. Replacing a dirty air filter and resetting fuel trims can often restore the system to its normal, efficient operation.

Conclusion: Fuel Trims as a Diagnostic Tool

Fuel trims are a vital aspect of modern engine management. They represent the engine computer’s ongoing effort to maintain the optimal air-fuel ratio for efficient and clean combustion. By monitoring short-term and long-term fuel trim values, technicians can gain valuable insights into potential engine problems, ranging from air intake restrictions to fuel delivery issues. Understanding “What Are Fuel Trims” empowers both car owners and professionals to better diagnose and maintain vehicle performance.